Overview of Semiconductor Mission of India

There is a lot of buzz around a word and industry of ‘Semiconductors’, not just in India but around the world. Let’s explore in this article why has it become talk of the nation.

“India will, in next five years, join the high-stake global stage of semiconductor manufacturing as it combines unparalleled design capabilities with USD 10 billion of incentives to draw manufacturers to set up new fabs and units that will cut dominance of Taiwan, South Korea and China”,

said Ashwini Vaishnaw, IT and Telecom Minister, India.

With this recent announcement by the Minister on February 29th, 2024, India’s mission of Semiconductors has got a substantial boost.

What is a Semiconductor?

A semiconductor is a substance that has specific electrical properties that enable it to serve as a foundation for computers and other electronic devices. It is typically a solid chemical element or compound that conducts electricity under certain conditions but not others. This makes it an ideal medium to control electrical current and everyday electrical appliances.

A substance that can conduct electricity is called the conductor and a substance that cannot conduct electricity is known as the insulator. Semiconductors have properties that sit between the conductor and insulator. A diode, integrated circuit (IC) and transistor are all made from semiconductors.

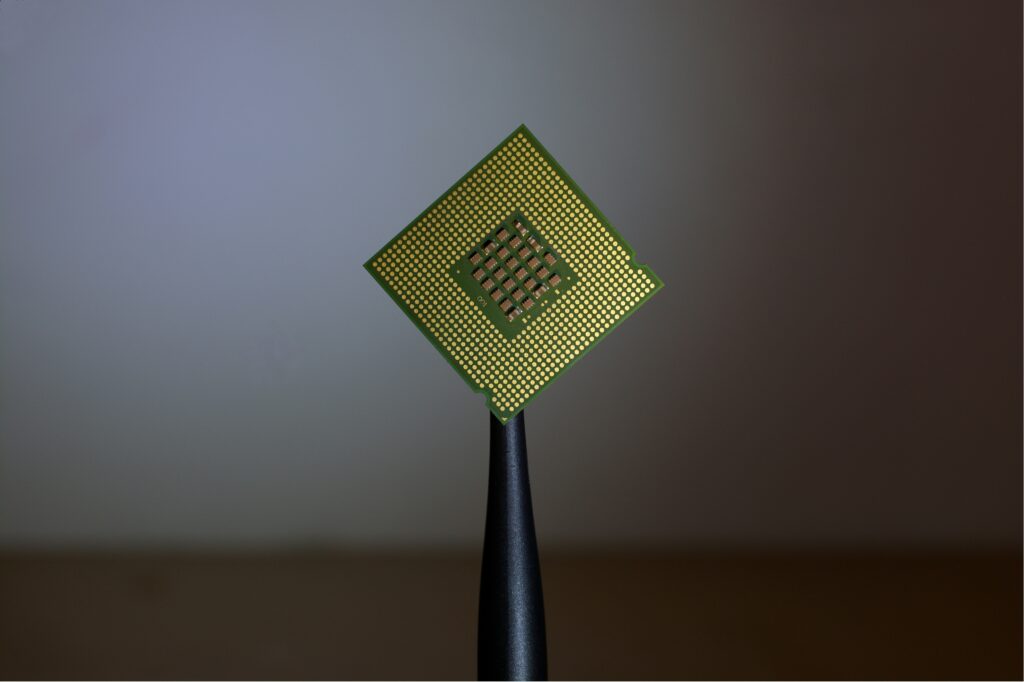

What is a Semiconductor Chip?

A semiconductor substance lies between the conductor and insulator. It controls and manages the flow of electric current in electronic equipment and devices. As a result, it is a popular component of electronic chips made for computing components and a variety of electronic devices, including solid-state storage.

A single semiconductor chip has as many transistors as all of the stones in the Great Pyramid in Giza, and today there are more than 100 billion integrated circuits in daily use around the world—that’s equal to the number of stars in our corner of the Milky Way galaxy.

For example, Apple’s A16 Bionic system-on-a-chip contains 16 billion transistors and can perform 17 trillion operations per second.

A semiconductor substance lies between the conductor and insulator. It controls and manages the flow of electric current in electronic equipment and devices. As a result, it is a popular component of electronic chips made for computing components and a variety of electronic devices, including solid-state storage.

Why the support for semiconductors production?

Semiconductor manufacturing is a highly complex process that involves various types of chips, wafer sizes, process technologies, materials, equipment, and design tools. Moreover, the manufacturing footprint is spread unevenly across the globe. Currently, more than 80% of semiconductor-manufacturing capacity is predominantly in Asia.

As shortages began manifesting in 2020, policymakers in the world recognized that the high concentration of chip manufacturing in Asia served to harm their competitive advantage and created massive supply chain vulnerabilities. Throw in pandemics, natural disasters, or potential military conflicts, and a bad situation had the potential to reach crisis levels.

In Deloitte’s 2023 global semiconductor industry outlook, it was noted that the landscape is uncertain and volatile, but also that the current downturn may be a pause that refreshes, allowing the industry to make collective progress on sustainability, talent, digital transformation, and realignment of manufacturing resources.

Applications of Semiconductor

Semiconductor materials are very useful in our everyday live below are some common examples.

- Computers: The chips and microprocessors which are called the core of computer are made of of semiconductors. These are the parts which helps the computers in processing data. Complex operations are not possible without these chips.

- Use in electronic devices: Basic electronic devices which we use such as Switches, electric circuits, diodes, transistors are made using semiconductors

- Light-emitting diodes (LEDs): LEDs are used in home for lightning these are semiconductor devices which produce light when current is passed through them. LEDs are used in everyday lighting applications, including energy-efficient bulbs for homes and offices, as well as in traffic signals, vehicle headlights, and electronic displays.

- Wearable Technology: The wearable devices such as smart watches now in latest smart rings have been built they are only possible using semiconductor technology. Because in them microprocessor chips are used which can be made using semiconductors

- Home Automation: Semiconductors are a crucial part of home automation systems, allowing for smart home devices like smart thermostats, smart lighting, smart security cameras, and voice-activated virtual assistants.

As it can be easily understood from the examples that semiconductors are largely used in the products and services that we use on every day basis. As technology would expand itself in the future, the need for semiconductors is going to rise upward.

Advantages of Semiconductor

Here are some advantages of a semiconductor:

- Miniaturization: Semiconductors are used in extremely small devices such as microprocessors and chips. They allows miniaturization in so that the devices which took a lot of space, with help of semiconductors can be made in small sizes.

- Energy Efficiency: As compared to other materials semiconductor is an energy efficient device. They consume lower energy compared to other materials while the electronic operations are performed.

- Light Emission: Certain semiconductor have the property to emit light when the electric current is passed through them. This made the LEDs (Light Emitting Diodes) possible and also the laser diodes.

- High Switching Speed: The switching speed in semiconductors in comparatively very high which allows fast switching in devices. This is important property because it saves time and lowers the complexity and also allows them to perform fast digital operations.

- Formation of IC: Integrated circuits (ICs) can incorporate millions of semiconductor devices on a single chip, leading to complex functionalities in a compact form.

Disadvantages of Semiconductor

Some of the disadvantages of a Semiconductor are:

- Temperature Vulnerability: Semiconductor gadgets can react strongly to changes in temperature, leading to shifts in how they work and how dependable they are.

- Expensive Production: Making semiconductors involves intricate processes and specialized facilities, resulting in high initial manufacturing expenses.

- Heat Tolerance Limits: Some semiconductors can’t endure high temperatures well. This could lead to their performance dropping or even failing.

- Reliance on Purity: The efficiency of semiconductors heavily depends on how pure they are. Even minor impurities can drastically change their electrical characteristics.

- Issues with Consistency: Over time, specific semiconductor devices might degrade or wear out, negatively affecting their dependability and lifespan.

India’s Semiconductor Mission

Three new semiconductor units have received approval from the Cabinet under the initiative “Development of Semiconductors and Display Manufacturing Ecosystems in India”.

- Semiconductor Fab (fabrication facility) with 50,000 wfsm capacity – at Dholera, Gujarat– Tata Electronics Private Limited (TEPL) will collaborate with Powerchip Semiconductor Manufacturing Corp (PSMC), Taiwan, to establish a semiconductor fab in Dholera, Gujarat, with an investment of INR 9100 billion (US$109.71 billion). PSMC has six semiconductor foundries in Taiwan. The fab’s capacity will be 50,000 wafer starts per month (wfsm), covering segments such as high-performance compute chips with 28 nm technology and power management chips for electric vehicles (EV), telecom, defense, automotive, consumer electronics, display, power electronics, etc.

- Semiconductor ATMP (Assembly, Test, Marking and Packaging) unit – at Morigaon, Assam– Tata Semiconductor Assembly and Test Pvt Ltd (TSAT) will set up a semiconductor unit in Morigaon, Assam, with an investment of INR 2700 million (US$325.99 million). TSAT is developing indigenous advanced semiconductor packaging technologies, including flip chip and ISIP (integrated system in package) technologies. The unit’s capacity will be 48 million per day, catering to segments such as automotive, electric vehicles, consumer electronics, telecom, mobile phones, etc.

- Semiconductor ATMP unit for specialized chips – at Sanand, Gujarat– CG Power, in partnership with Renesas Electronics Corporation, Japan, and Stars Microelectronics, Thailand, will establish a semiconductor unit in Sanand, Gujarat, with an investment of INR 760 million (US$91.63 million). Renesas, a semiconductor company specializing in chips, operates 12 semiconductor facilities and is a key player in microcontrollers, analog, power, and System on Chip (SoC) products. The CG power semiconductor unit will manufacture chips for consumer, industrial, automotive, and power applications, with a capacity of 15 million per day.

Uttar Pradesh (UP) Government Initiatives

The Uttar Pradesh government has announced a massive subsidy and exemption programme for semiconductor investors under the newly ratified UP Semiconductor Policy 2024. All the incentives in the scheme would be over and above the ones offered by the Centre under its Modified Programme for Semiconductors and Display Fab Ecosystem.

Those investing up to ₹200 crores can avail themselves of this incentive, with units investing up to ₹7 crores also eligible for the interest subsidy. The subsidies encompass a 50% capital subsidy sanctioned by the central government and a 75% subsidy on land purchases, based on prevailing sector rates, for up to 200 acres.

The state has also pledged to exempt investors from electricity duty for a decade, along with providing double power grid networks for semiconductor fabrication units.

Complementing the subsidy package is a robust focus on skill development and training initiatives, aimed at cultivating a skilled workforce adept in chip design and manufacturing for which up to ₹3 crores will be allocated for five years, wherein up to ₹60 lakhs per year will be used for organising faculty training, technical workshops, awareness programmes, and expert lectures. The government will also provide annual financial assistance of ₹20,000 for up to 500 students each for five years under the Chief Minister Internship Scheme. The focus of this will be on B.Tech and M.Tech graduates.

Conclusion

Setting up semiconductor plants for indigenous manufacturing is a pivotal step considering our increasing dependence on electronic products. Just being the assembler will not yield the economic results to India, so it has to contribute to the process of production. The collaborative effort of both Central and State governments will certainly bring about the change that India needs in terms of leveraging the manufacturing sector for its economic growth.

Knowledge-sharing platform is aimed at providing analytical insights into Economy, Public Policy and Foreign Policy.