Introduction: Renewable Energy Sector in India

India is the third highest energy consuming country in the world as of 2021. According to the International Energy Agency, India’s energy requirement is expected to be the highest globally in the current decade.

To meet this great energy demand in an optimal way, a large portion of that will come from renewable energy sources. The world is moving towards more renewable energy gradually, and India is no exception. India has announced its intentions to have net zero carbon emissions by 2070, and meet 50% of its energy requirements through renewable energy sources by 2030. It is already making strides towards this.

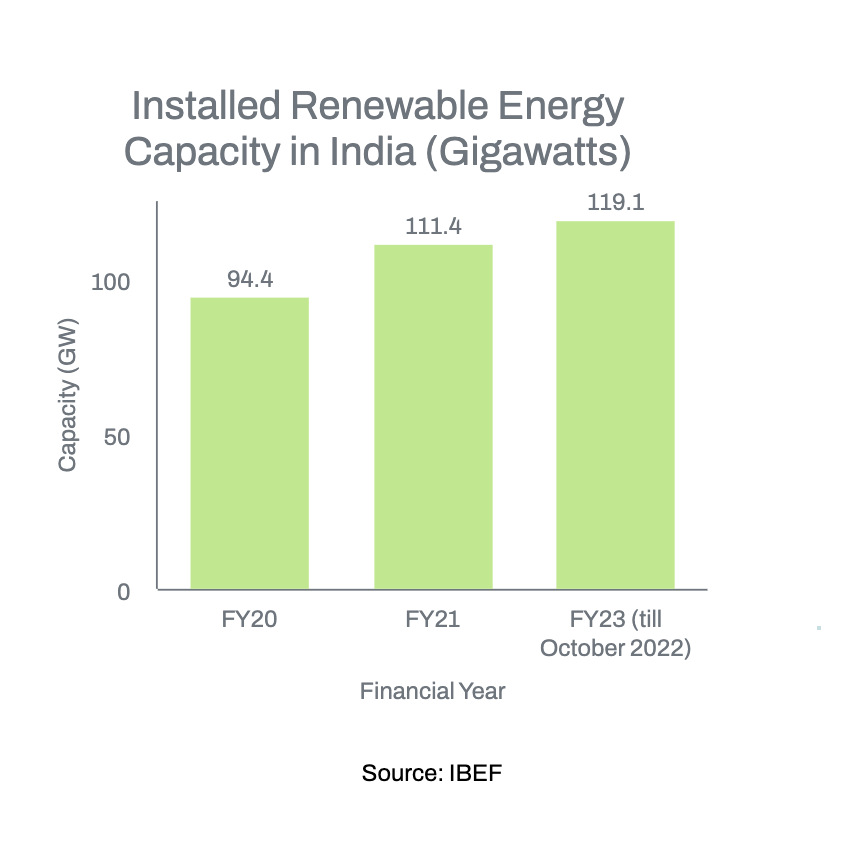

In 2020, India was ranked fourth in wind power, fifth in solar power and fourth in renewable power installed capacity. The total renewable power installed capacity grew with a cumulative annual growth rate of 15.92% between FY16 and FY22. As of October 2022, over 40% of the overall installed power capacity in India is renewable energy capacity including hydropower.

The Ministry of New and Renewable Energy has set a target of having a 450 Gigawatt installed energy capacity by 2030, and 60% of which is expected from solar energy. The Government of India is supporting these targets through its various initiatives, one of them being the Production Linked Incentive (PLI) scheme for High Efficiency Solar PV modules. This scheme is a big step towards enhancing domestic manufacturing capabilities domestically, and attracting foreign investment in this industry. Meeting the energy demands domestically is also a big opportunity for the country and investors. India has also initiated the International Solar Alliance consisting of 123 countries that lie between the tropic of cancer and the tropic of capricorn, with an objective of efficient consumption of solar energy and reducing dependency on fossil fuels.

The High Efficiency Solar PV Module Industry manufactures solar panels, which are also known as photovoltaic (PV) modules. PV modules convert sunlight into electricity with high efficiency. PV modules can generate a significant amount of electrical energy from a relatively small area, and are important parts of the renewable energy industry. The solar panels produced in this sector are finished goods, or final products used to generate electricity from sunlight.

NIC & NCO

Electric power generation using solar PV modules in the National Industries Classification comes under Section D (Electricity, Gas, Steam and Air Condition Supply), Group 351 (Electric power generation, transmission and distribution), Class 3510, Subclass 35105 – Electric power generation using solar energy. The National Classification of Occupations has multiple occupations that are a part of the solar PV module manufacturing industry. Some of them include: 8212.2301 – Module Assembly Technician. “Module Assembly Technician is responsible for fixing frames and junction box in the solar module”. 8212.2302 – Module Soldering Operator. “Module Soldering Operator is responsible for connecting solar cells by soldering to form a solar module”.

States

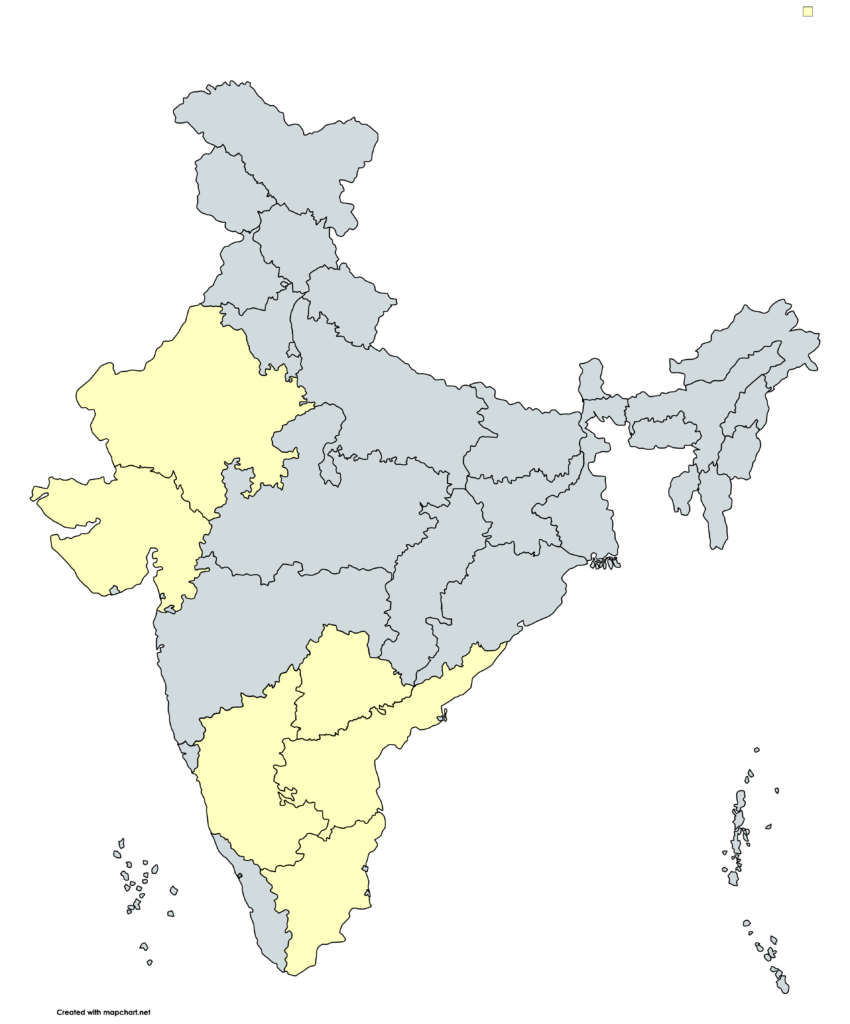

The states that have a strong presence in the Solar PV module manufacturing sector include: Gujarat (Key manufacturers include Adani Solar, Waree, Goldi Solar), Tamil Nadu (Vikram Solar), Telangana (RenewSys, Premier Energies), Rajasthan (Adani Solar, Waree), Andhra Pradesh (Vikram Solar), and Karnataka (Tata Power Solar) They have a number of solar energy projects and high manufacturing activity in this sector.

Raw Material

The major raw materials required for producing Solar PV modules are silicon, copper, and aluminium. Finished solar panels are also 80% glass by weight.

- Silicon is the most important raw material used to make the solar cells that are embedded in the solar panels. Silicon can be purified and processed into various forms like crystalline and amorphous, which are used in different types of solar cells.

- Aluminium is used in the structural components of solar panels.

- Copper is used in the electrical connections within solar panels and also in the production of the inverters used to convert the generated direct current into consumable alternate current.

- Glass is used as a cover for the panel to protect the solar cell while also allowing sunlight to pass through.

- Encapsulants are used to seal and protect the solar cell from contaminants and moisture in the panel, and are often made using materials like ethylene vinyl acetate (EVA) or polyvinyl fluoride (PVF).

Infrastructure Required

The infrastructure required for the high efficiency solar PV module manufacturing sector primarily includes electricity, water, warehousing, and transportation. The manufacturing process typically takes place in specialized factories, which may require specialized equipment and infrastructure.

India has ambitious goals for its renewable energy sector, of which solar energy is a major part. It is expected to grow significantly in the upcoming years as renewable and clean energy becomes more important. One aspect of the solar module industry that is a challenge and that will need to be resolved is the high costs of manufacturing solar cells and setting up solar power plants. Currently, India has a cell manufacturing capacity of 4.3 Gigawatts and module manufacturing capacity of around 18 Gigawatts (IEEFA), however the production facilities operate at 40-50% of the capacity due to challenges including supply chain issues and high capital requirements. By 2040, it is expected that around 49% of the total electricity generated will be from renewable sources. Batteries for storing electricity will become more efficient, cutting solar energy costs by 66% as compared to now. India will save an estimated Rs. 54,000 crore (US$ 8.43 billion) annually by using renewable energy instead of coal.

The PLI scheme for High Efficiency Solar PV modules with a total outlay of Rs. 24,000 crore will help provide a huge boost in enhancing the domestic manufacturing capacity for solar PV modules in India by providing incentives to the manufacturers. It will also help increase exports in this industry. This will also help India to meet its own domestic solar module demand, as well as create new jobs in the industry. It may also encourage research and development activities by manufacturers, for which there is huge scope and need in this industry. This can lead to more efficient solar PV modules, and also drive down the cost of production over time.

Dhruv Chaudhari

Dhruv Chaudhari is a Research Intern at Tatvita. Presently he is pursuing his bachelors in the Liberal Arts department at the Savitribai Phule Pune University.